Indevolt battery optimizer: A technological breakthrough for balcony solar power systems with storage

As stackable balcony solar systems with storage become increasingly common in households, discrepancies in usable battery capacity and technical issues arising from combining old and new batteries are becoming more apparent. The total usable energy of the system is often limited by the so-called “bottleneck effect,” where the weakest battery cell significantly restricts overall performance. This becomes particularly critical if a cell fails completely, as it can bring the entire system to a halt.

Indevolt is now the first company to launch a solar storage unit for solar systems that comes standard with integrated battery optimizer technology. How does this innovation break through previous technical limitations — and what does it mean for the future of home energy storage? This article provides the answers.

Battery capacity does not equal usable energy

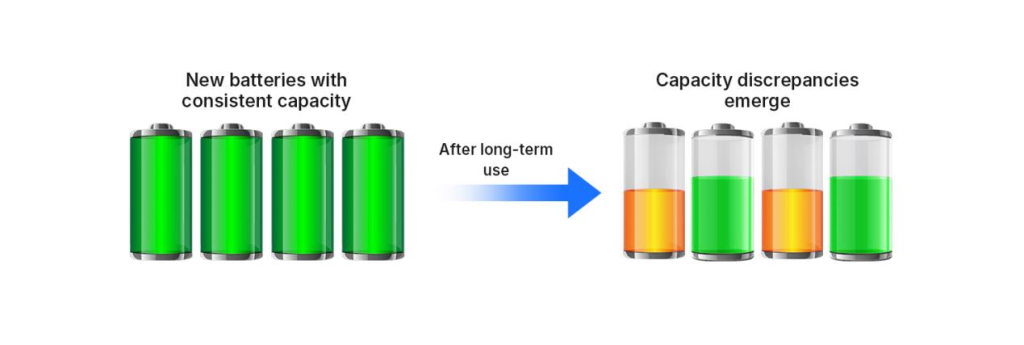

In home energy storage systems, the actual amount of usable energy is of crucial importance. Although batteries from the same series deliver similar performance at the beginning, aging processes, charging and discharging cycles, as well as fluctuations in temperature and humidity, lead to a significant loss of performance over time.

When the electricity demand in a household increases, the original storage capacity is no longer sufficient — new batteries are added as a supplement. However, the mixed operation of old and new batteries exacerbates the problem:

During charging, old batteries have higher internal resistance and lower efficiency, which causes new batteries to remain inactive. As a result, the charging performance of the system decreases. During discharging, old batteries run out of power faster, while new batteries become overloaded — this leads to uneven wear and a shorter service life.

Whether due to aging or mixed operation — all these factors reduce the available storage capacity and thus the actual utility of the system.

Why does an aged battery slow down the entire system?

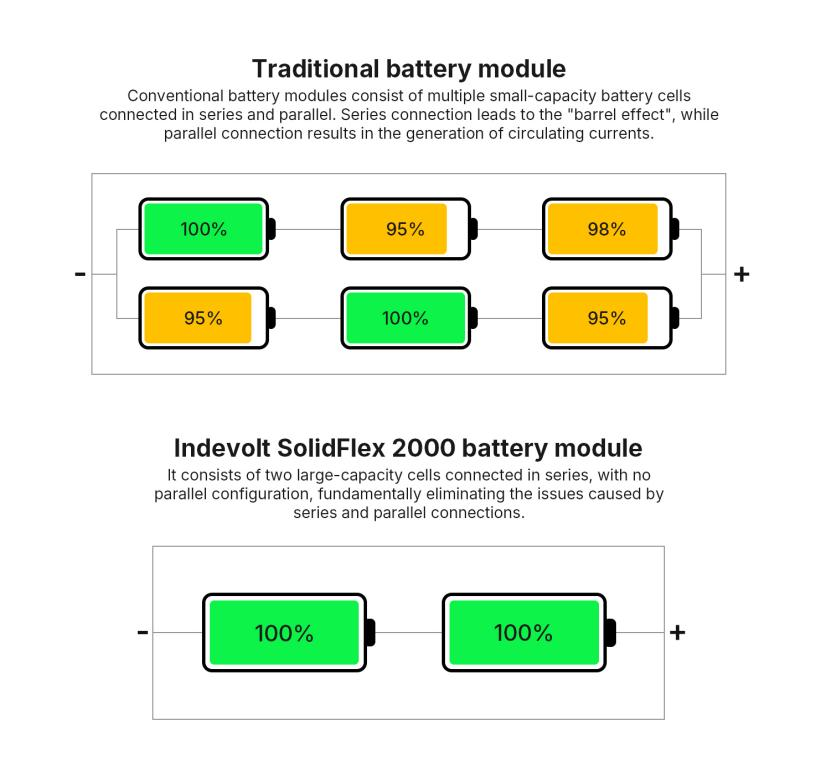

Let’s start with the technical basics of traditional series-parallel connection: At its core, it is a central parallel connection — all positive terminals of the batteries are connected to one another, and all negative terminals are connected in parallel. This creates an operating mode characterized by “uniform voltage and current superposition.”

The critical disadvantage of this structure is that when different battery groups have varying voltages or internal resistances, the current flows counter to the logic of energy transfer: it moves from battery groups with low internal resistance to those with high internal resistance. This forms an ineffective current loop within the closed circuit.

The main cause of this ineffective current loop is the inconsistency in performance between battery groups, which is explained in detail below:

1. Voltage difference: Passive discharge from “high voltage” to “low voltage”

The degree of aging, operating temperature, and initial capacity of battery packs can lead to differences, meaning their voltages are not identical when fully charged. For example, due to its short service life and the good condition of its cells, Battery Pack A reaches a full charge voltage of 52 V. In contrast, Battery Pack B — after years of frequent charge-discharge cycles and significant aging — only reaches a full charge voltage of 50 V. When the two are connected in parallel, the high voltage of Battery Pack A causes current to flow to Battery Pack B. As a result, part of the energy that should otherwise be fully used for power supply forms a “discharge-charge cycle” within the batteries. This current is thus a complete waste of energy. Furthermore, it accelerates the overcharging of Battery Pack B and the over-discharging of Battery Pack A, which further impairs the batteries’ service life.

2. Differences in internal resistance: “conflicts” between “low internal resistance” and “high internal resistance”

Internal resistance is one of the core factors contributing to the inefficiency of a power source. Its magnitude directly affects the output power and service life of the device. For a battery with increased internal resistance, Ohm’s Law (I=U/R) leads to a reduction in output current. In contrast, healthy battery packs are forced to absorb an excessive amount of current. This unbalanced load not only results in an inefficient energy cycle between battery packs but also — due to the heat generated by internal resistance — accelerates overall aging, creating a vicious cycle of “deterioration of the current loop → imbalance in internal resistance → further deterioration of the current loop.”

3. Uneven temperature distribution: The amplifying effect of “temperature differences”

If the cooling system fails to precisely regulate temperature during battery operation, this leads to uneven temperature distribution between individual battery packs — and temperature and internal resistance are closely linked: For every 10 °C increase in temperature, the internal resistance of a battery pack decreases by approximately 5%. Battery packs with low temperatures and high internal resistance have lower current output capabilities, while those with high temperatures and low internal resistance deliver current far exceeding the normal amount. This exacerbates the issues of energy waste and battery damage within the system.

Battery optimizer – For the optimal condition of each individual battery

The above analysis shows that traditional energy storage systems suffer from the “barrel effect” (Holzfass-Effekt), primarily due to the feedback effects that arise between battery packs. This not only wastes total capacity but also accelerates system wear. This technical problem is now solved as a groundbreaking innovation by the Indevolt SolidFlex 2000 balcony energy storage system. The built-in battery optimizer is equipped with an independent system for each battery pack, endowing the energy storage system with a kind of “intelligent neural network” and thus resolving the traditional issue at a fundamental level. Below, we will analyze in depth how this innovative technology reshapes the efficiency and lifespan of household energy storage.

What is a battery optimizer?

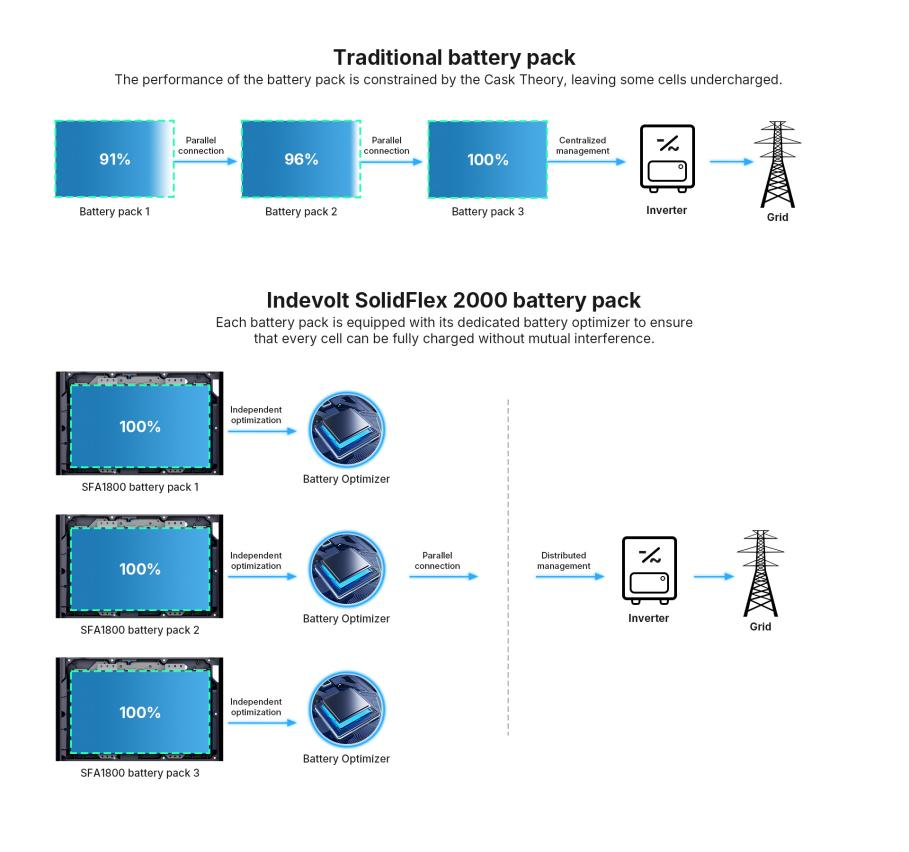

First, let’s take a look at the main architecture of battery optimizers and traditional central systems.

By installing an energy optimizer in each battery pack, the system can mon.itor the operating status of every individual battery cell in real time and regulate each cell independently. It precisely controls parameters such as capacity loss, voltage changes, and temperature changes of individual modules. At the same time, through dynamic balance regulation — which includes dynamically adjusting the charge and discharge threshold values according to the battery state, adopting a strategy that prioritizes the condition of the batteries (to give priority to using batteries in good condition and thereby reduce the number of charge cycles of aging batteries), and actively balancing the voltage of all battery packs — the “barrel effect” (Holzfass-Effekt), in which weaker batteries impair overall performance, is avoided.

The specific advantages are as follows:

1. Increased efficiency and longer service life

Through modular control, each battery pack can operate independently. Healthy batteries are used more intensively, while weakened ones are protected. This improves overall efficiency and extends the system’s service life.

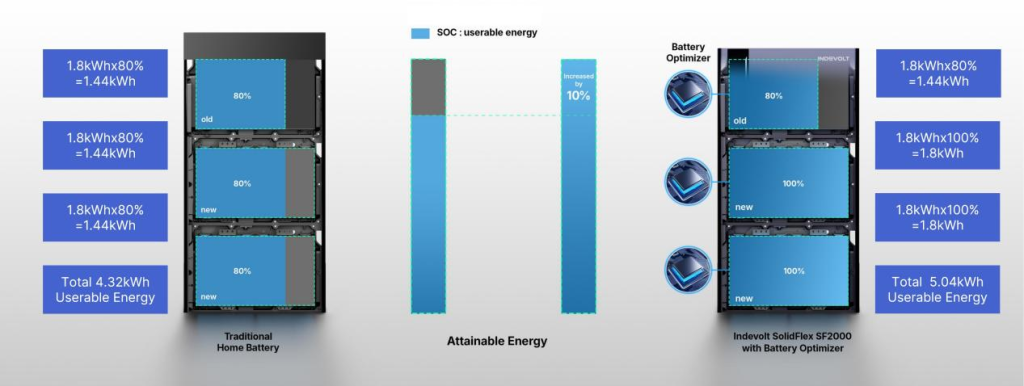

2. Higher usable capacity

In a traditional battery system, when one old battery is connected in parallel with two new batteries, the total system capacity is limited by the oldest battery (the one with the poorest performance). With a battery optimizer, each battery is charged and discharged independently. This allows the old battery to exert its actual capacity, while the new batteries can operate at full performance. As a result, the system’s usable capacity increases by at least 10%.

Example Calculation for the SolidFlex 2000 (1 Old + 2 New Batteries):

| Scenario | Formula | Usable Capacity |

| Classic (all 80%) | 1.8kWh × 80% × 3 | 4.32kWh |

| With Optimizers | 1.8kWh×80% + 1.8kWh×100% + 1.8kWh×100% | 5.04kWh |

| Increase | 0.72kWh | +16.7% |

3. Fault isolation in milliseconds

Traditional stacked energy storage systems use a centralized topology. When a single battery module fails, a mechanism is triggered to forcefully shut down the entire group—resulting in reduced system efficiency and power supply reliability. Battery optimizers, which are based on a distributed intelligent management architecture, feature a fault isolation function that operates in the millisecond range. When they detect an anomaly in the charging or discharging process of a battery module, they immediately disconnect the faulty module channel. Meanwhile, all other functional modules continue to operate at full capacity.

4. Active balancing

As part of the Battery Management System (BMS), we achieve precise voltage calibration between two cells through a special balancing circuit technology: On one hand, excess energy from highly charged cells is accurately dissipated. This prevents accelerated aging of some batteries due to long-term overcharging, ensuring all batteries in the group always maintain a similar state of charge—significantly improving the consistency of the battery group. On the other hand, we reduce cumulative voltage deviations of individual cells during charging and discharging, and minimize irreversible damage (such as aging and electrolyte decomposition) caused by long-term imbalances. This prevents a single cell from limiting the capacity of the entire battery set due to the “barrel effect” (Holzfass-Effekt), thereby significantly extending the service life of the battery set while enhancing the uniformity of the battery pack and avoiding limitations imposed by individual weak cells.

5. Solving problems at the root

The more cells there are, the more pronounced the issues of system capacity degradation, shortened service life, and efficiency loss—problems that can even lead to potential safety risks.

To address this industry-wide challenge, the Indevolt SolidFlex 2000 adopts an innovative, minimalist design: it uses two high-capacity cells connected in series and completely eliminates parallel connections. By significantly reducing the number of cells, the probability of losses caused by series-connection balancing is fundamentally reduced, and performance losses (resulting from inconsistent cells in traditional series-parallel configurations) are perfectly avoided. This design not only enables a substantial improvement in system performance but also offers numerous advantages, including increased efficiency, longer service life, lower risks, and higher usable capacity.

Conclusion: Efficiency, reliability, and future-proofing

In summary, it can be stated that while traditional energy storage systems are still limited by the “barrel effect” (Holzfass-Effekt) and the associated performance bottlenecks, the Indevolt SolidFlex 2000 solves the problem of imbalances within the battery pack through a combination of three technologies: “Battery Optimizer + High-Performance Cells + Special Balancing Circuit.” This enables independent management and optimization of each individual battery pack, increases usable capacity, extends battery service life, and improves the return on investment for energy storage.