Fire protection reimagined: How semi-solid lithium batteries are revolutionising the safety of home storage systems

Plug-and-play solar systems are conquering the market with their ease of use. Their simple design and intuitive operation make them a cheaper and better alternative to conventional solar systems. This technology gives every household access to renewable, cheaper and greener energy, which was previously denied due to complex processes and immense financial costs.

The widespread use of this technology in Europe, brought about by massive cost reductions and efficiency gains, has now brought a new issue to the forefront: the issue of safety, in particular fire safety, is a major concern for many, especially as the risk of fire is often most imminent in storage facilities. This is where semi-solid lithium batteries come into play.

In order to clarify how a problem should be solved, the first question that arises is:

Why do conventional LFP batteries catch fire in the first place?

A battery normally has four components: cathodes, anodes, separators and a current-conducting material, the electrolytes. Lithium iron phosphate (LFP) batteries are considered to be significantly safer than NCM cells because their cathodes release hardly any oxygen even at high temperatures. This makes LFP batteries significantly safer to use for solar storage than outdated NCM batteries. However, they also have a serious weakness: the liquid electrolytes. When heated to high temperatures, these electrolytes produce highly flammable gases such as methane or ethane, which can easily cause fires when they come into contact with oxygen. In addition, the pressure inside the battery increases, which can cause explosions in serious cases.

The following would be the main causes of such reactions in electrolytes:

- Unfavourable environmental and operating conditions: Direct sunlight, high ambient temperatures or internal overload can lead to heat build-up and uncontrolled temperature rise.

- Defective separators as a cause of short circuits: Mechanical damage or, in serious cases, the disintegration of the separators can lead to short circuits and is therefore considered the main cause of fires.

- Side reactions of the anode: At high temperatures, it is possible for graphite as an anode material to react with the electrolyte, releasing additional heat and gases.

Although modern batteries are equipped with a BMS (battery management system) that warns the user at an early stage if a fire is imminent, it cannot prevent fires from occurring. Semi-solid batteries are the solution here.

How do semi-solid batteries solve the safety problem?

As explained above, the root of the problem with LFP cells is their liquid electrolytes. Solid electrolyte batteries are not highly flammable, but they suffer from poor ion permeability and contact problems between the electrolytes and the electrode, which limits performance and service life.

The solution: semi-solid batteries combine the best of both worlds.

They replace part of the liquid electrolyte with a solid or gel-like electrolyte. This significantly reduces flammability without compromising conductivity. Compared to both, semi-solid electrolytes combine the fire resistance of solid electrolytes with the efficiency of liquid electrolytes. More specifically, semi-solid electrolytes offer the following advantages.

- Lower flammability of electrolytes Solids are more temperature-resistant and do not evaporate as easily as liquids. When used alongside separators, they significantly reduce the proportion of highly flammable solvents.

- Gel structure prevents evaporation and leakage The addition of solid electrolytes causes the electrolyte to take on a gel-like structure that cannot evaporate. Even in the event of an internal short circuit, the conditions for a fire to start do not exist.

- Resistance to lithium dendrites The growth of lithium dendrites that penetrate the membrane is the main cause of short circuits and fires in conventional lithium batteries. The gel-like structure of semi-solid batteries can prevent lithium dendrites from penetrating and reduce the risk of membrane holes. Gel structure blocks the growth of dendrites – a major cause of short circuits in conventional cells.

- Formation of a more stable SEI layer (solid electrolyte interphase) The solid component forms a more stable boundary layer to the graphite anode, minimises side reactions and increases the threshold temperature for thermal runaways. The solid components and the SEI layer result in increased stability and heat resistance.

All of this has been proven with the help of laboratory tests, which are described below

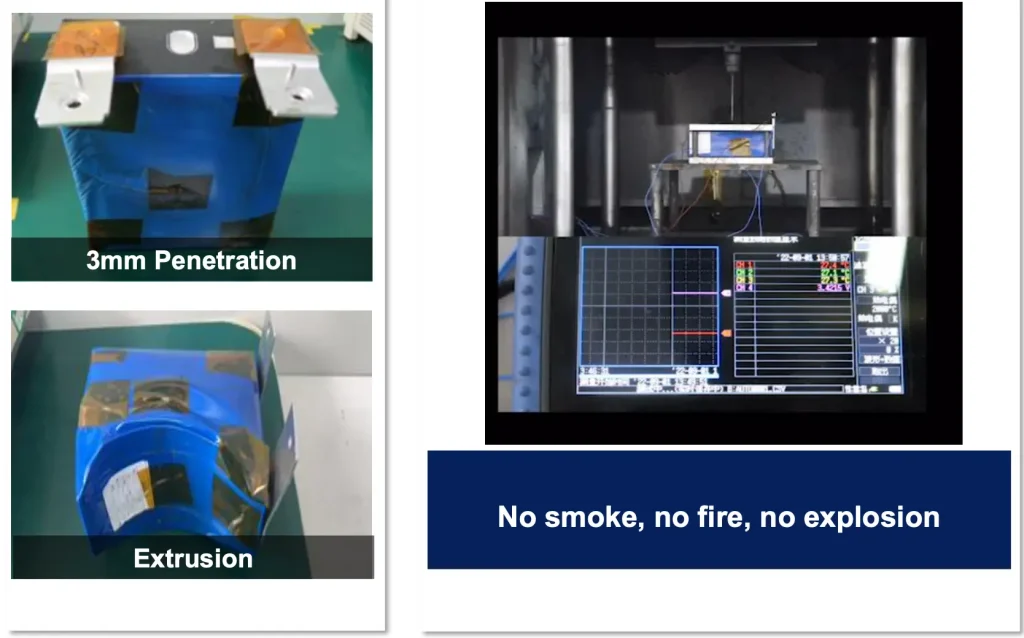

Internal short-circuit prevention test:

When pierced with a 3 mm steel needle, the semi-solid cell showed no smoke, fire or explosion.

Heat resistance test:

Even at 160°C inside an oven, the cell remained stable – there was no thermal reaction.

Overcharge safety test:

Even when overcharged to 25 V (0.5 C rate) – well above the nominal voltage – no gas emissions were measured.

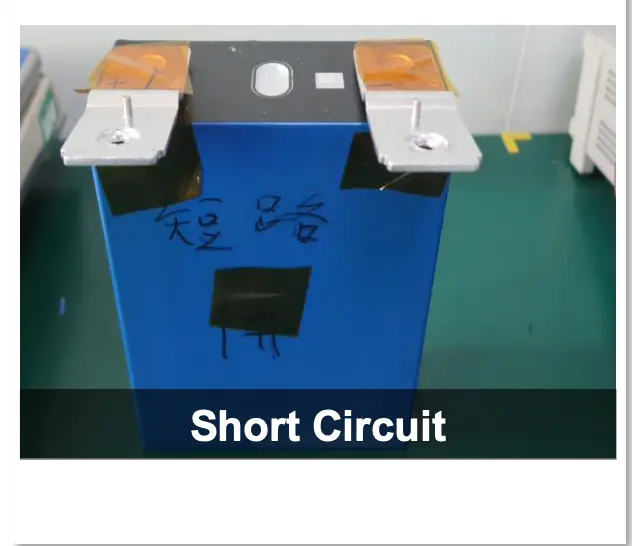

External short circuit:

A short circuit caused by a <1 mΩ conductor did not result in any heat generation or thermal runaway.

All of this means that semi-solid lithium batteries are the future for conventional solar systems

With the advent of plug-and-play solar systems, demand for safe and low-maintenance energy storage systems is growing. Semi-solid lithium iron phosphate batteries offer exactly that: a fire-protected, stable and durable solution for home use.

They drastically reduce the risk of fire and explosion – while ensuring that performance and service life are not compromised. Switching to semi-solid technology is therefore not only a safety promise for your home, it is a step towards a more technologically advanced future.